HYDRAULIC PRESS

For deep drawing/drawing

For cold forging

H-S SERIES

▲ h1s200e

Main specifications

| Max.pressing capacity | 2000kN |

| Table dimensions | 1300×1000mm |

| Daylight | 1350mm |

| Stroke length | 900mm |

| Die cushion capacity | 800kN |

| Die cushion stroke | 350mm |

H-S SERIES

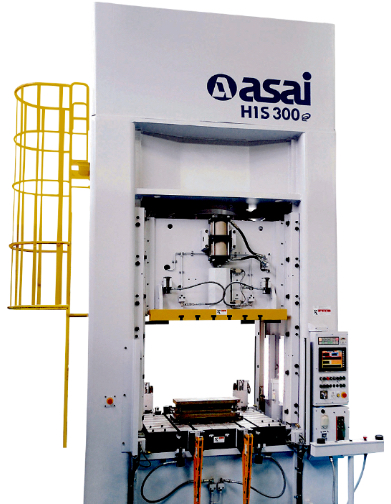

▲ H1S300e

Main specifications

| Max.pressing capacity | 3000kN |

| Table dimensions | 1300×1200mm |

| Daylight | 1400mm |

| Stroke length | 900mm |

| Die cushion capacity | 1200kN |

| Die cushion stroke | 350mm |

H-S SERIES

▲ H3S500e

Main specifications

| Max.pressing capacity | 5000kN |

| Table dimensions | 2500×1600mm |

| Daylight | 1500mm |

| Stroke length | 1000mm |

| Die cushion capacity | 2500kN |

| Die cushion stroke | 300mm |

PRT SERIES

▲ PRT1500e

Main specifications

| Max.pressing capacity | 15000kN |

| Table dimensions | 3000×2000mm |

| Daylight | 1800mm |

| Stroke length | 1300mm |

| Die cushion capacity | 3000kN |

| Die cushion stroke | 350mm |

H-S SERIES

▲ H1S120e

Main specifications

| Max.pressing capacity | 1200kN |

| Table dimensions | 600×500mm |

| Daylight | 800mm |

| Stroke length | 400mm |

EFP SERIES

▲ EFP-300H

Main specifications

| Max.pressing capacity | 3000kN |

| Table dimensions | 400×400mm |

| Daylight | 550mm |

| Stroke length | 150mm |

EFP SERIES

▲ EFP-1000H

Main specifications

| Max.pressing capacity | 10000kN |

| Table dimensions | 800×800mm |

| Daylight | 550mm |

| Stroke length | 250mm |

H-S SERIES

▲ H1S1500e

Main specifications

| Max.pressing capacity | 15000kN |

| Table dimensions | 1500×1500mm |

| Daylight | 2000mm |

| Stroke length | 1500mm |

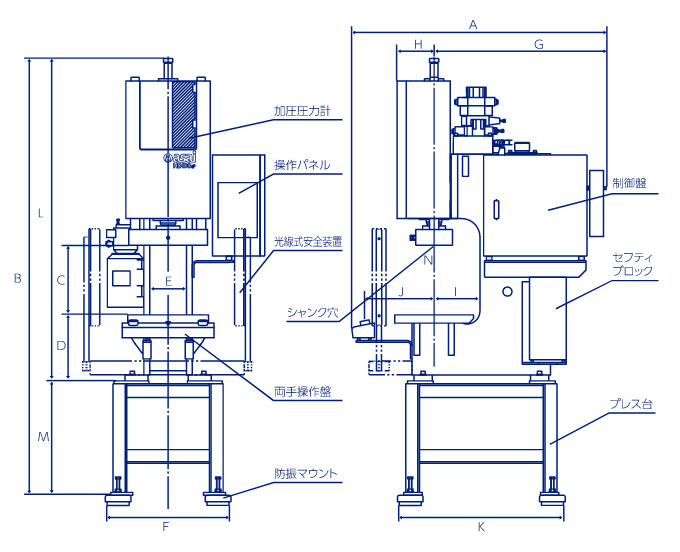

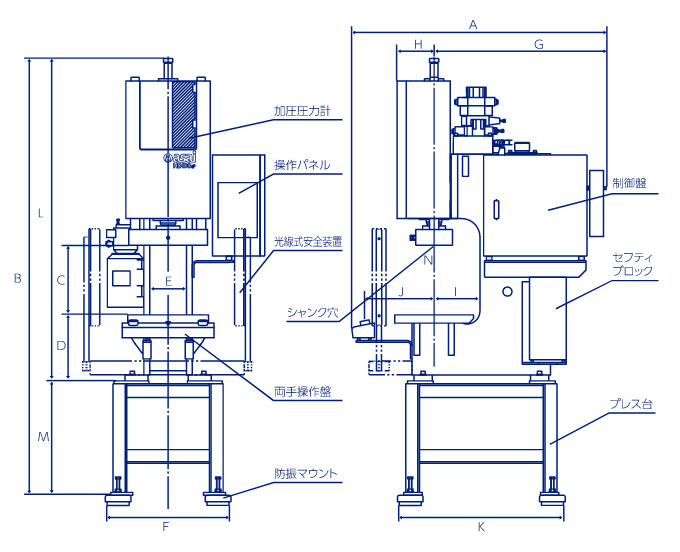

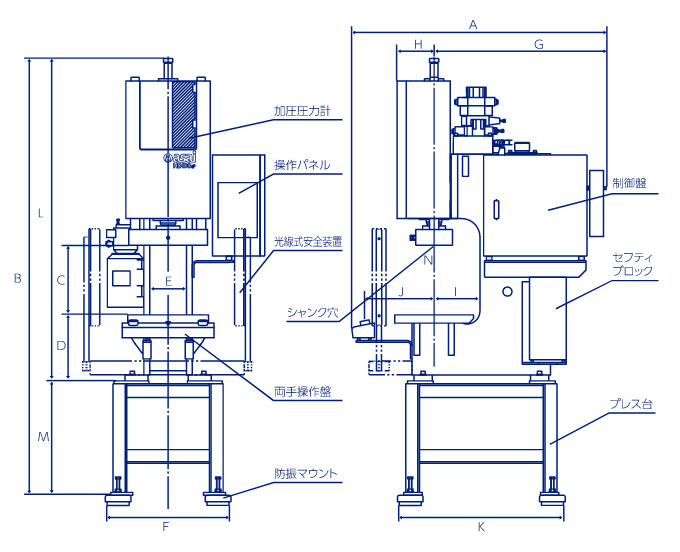

H/PRT SERIES

▲ HD100e

Main specifications

| HD 100e | HD 150e | HD 200e | HD 300e | HD 400e | ||

| Pressurizing | kN | 100 | 150 | 200 | 300 | 400 |

| Daylight | mm | 380 | 400 | 500 | 550 | 550 |

| stroke | mm | 200 | 200 | 250 | 250 | 250 |

| Descend speed | mm/sec | 260 | 260 | 250 | 250 | 235 |

| Press speed | mm/sec | 28 | 28 | 23 | 23 | 23.5 |

| Climb speed | mm/sec | 260 | 260 | 220 | 220 | 230 |

| Bolster | mm | 440×430 | 500×400 | 550×400 | 700×400 | 700×400 |

| slide | mm | 430×200 | 460×200 | 550×250 | 550×250 | 700×300 |

| Upper weight | kg | 50 | 50 | 100 | 100 | 100 |

| Max-hydraulic | MPa | 15.7 | 23.5 | 14.6 | 22 | 14.1 |

| Stopper | mm | 0〜90 | 0〜90 | 0〜120 | 0〜120 | 0〜120 |

| Oil tank | ℓ | 13 | 16 | 20 | 20 | 40 |

| Motor capacity | kw | 2.2 | 3.7 | 3.7 | 5.5 | 7.5 |

| weight | kg | 865 | 1115 | 1615 | 2065 | 2950 |

Size List/mm

| HD | 100e | 150e | 200e | 300e | 400e |

| A | 1340 | 1340 | 1510 | 1620 | 1680 |

| B | 2300 | 2255 | 2560 | 2685 | 2845 |

| C | 380 | 400 | 500 | 550 | 550 |

| D | 360 | 376 | 405 | 515 | 620 |

| E | 200 | 228 | 280 | 190 | 248 |

| F | 625 | 560 | 820 | 820 | 700 |

| G | 890 | 890 | 1050 | 1140 | 1175 |

| H | 200 | 220 | 245 | 240 | 300 |

| I | 250 | 250 | 250 | 250 | 250 |

| J | 375 | 380 | 390 | 410 | 435 |

| K | 845 | 930 | 985 | 985 | 1150 |

| L | 1760 | 1836 | 2170 | 2405 | 2670 |

| M | 540 | 419 | 390 | 280 | 175 |

| N |

Standard equipment

| ・Safety card | ・Pressure table | ・Touch panel |

| ・Signal tower | ・compatible | ・digital setting |

| ・Buzzer | ・Automation contact | ・Slide position setting |

| ・oil cooler | ・English | ・Motion judgment |

| ・Pressurized display | ・Different voltage | ・Adjust record |

Standard options

| ・Safety card | ・Pressure table | ・Touch panel |

| ・Signal tower | ・compatible | ・digital setting |

| ・Buzzer | ・Automation contact | ・Slide position setting |

| ・oil cooler | ・English | ・Motion judgment |

Particular options

| ・Safety card | ・Pressure table | ・Touch panel |

| ・Signal tower | ・compatible | ・digital setting |

| ・Buzzer | ・Automation contact | ・Slide position setting |

| ・oil cooler | ・English | ・Motion judgment |

| ・Pressurized display | ・Different voltage | ・Adjust record |

H/PRT SERIES

▲ HCS500e

Main specifications

| HCS500e | HCS600e | HCS800e | HCS1000e | ||

| Pressurizing | kN | 500 | 600 | 800 | 1000 |

| Daylight | mm | 550 | 550 | 600 | 600 |

| stroke | mm | 250 | 250 | 300 | 300 |

| Descend speed | mm/sec | 235 | 235 | 225 | 225 |

| Press speed | mm/sec | 23.5 | 23.5 | 18 | 18 |

| Climb speed | mm/sec | 230 | 230 | 210 | 210 |

| Bolster | mm | 750×400 | 750×400 | 1000×600 | 1100×630 |

| slide | mm | 750×400 | 750×400 | 750×400 | 800×400 |

| Upper weight | kg | 100 | 100 | 150 | 200 |

| Max-hydraulic | MPa | 17.6 | 21.2 | 19.3 | 24.1 |

| Stopper | mm | 0〜150 | 0〜150 | 0〜150 | 0〜150 |

| Oil tank | ℓ | 40 | 40 | 50 | 50 |

| Motor capacity | kw | 11 | 11 | 11 | 15 |

| weight | kg | 3790 | 4170 | 6700 | 9470 |

Size List/mm

| HCS | 500e | 600e | 800e | 1000e |

| A | 1780 | 1780 | 2090 | 2270 |

| B | 1375 | 1375 | 1340 | 1460 |

| C | 2985 | 3020 | 3315 | 3400 |

| D | 550 | 550 | 600 | 600 |

| E | 785 | 785 | 815 | 850 |

| F | 240 | 240 | 540 | 580 |

| G | 700 | 880 | 1020 | 1140 |

| H | 1210 | 1210 | 1520 | 1700 |

| I | 400 | 400 | 450 | 450 |

| J | 250 | 250 | 320 | 350 |

| K | 505 | 505 | 505 | 505 |

| L | 1240 | 1390 | 1555 | 1790 |

| Machine mass | 3900 | 4340 | 6600 | 9000 |

Standard equipment

| ・Dual hand operation panel |

・Failure diagnosis device | ・Safety block |

| ・Main breaker | ・Emergency stop button | ・Sequencer control |

| ・Electric lower limit stopper | ||

| ・Monochrome touch panel(pressure holding timer / abnormality display / accumulation timer / status monitor / trouble monitor / production counter) | ||

Standard options

| ・Special table | ・Special color | ・Touch panel |

| ・Actuating by external signal | ・Photo-electric safety device | ・Air blow circuit |

| ・Slide gravity fall prevention circuit | ・Vibration isolating mount | ・One cycle motion |

Special options

| ・Safety guard | ・Pressur control device | ・Touch panel colorization |

| ・Signal tower | ・Negative pressuer correspondence | ・Pressing ,speed digital setting |

| ・Air-cooled oil cooler | ・English specification | ・Slide position setting |

| ・oil cooler | ・English | ・Motion judgment |

| ・Pressing digital display | ・Different voltage specification | ・Adjust position storage |

H/PRT SERIES

▲ HOS500e

Main specifications

| HD | 100e | 150e | 200e | 300e | 400e | |

| Pressurizing | kN | 100 | 150 | 200 | 300 | 400 |

| Daylight | mm | 380 | 400 | 500 | 550 | 550 |

| stroke | mm | 200 | 200 | 250 | 250 | 250 |

| Descend speed | mm/sec | 260 | 260 | 250 | 250 | 235 |

| Press speed | mm/sec | 28 | 28 | 23 | 23 | 23.5 |

| Climb speed | mm/sec | 260 | 260 | 220 | 220 | 230 |

| Bolster | mm | 440×430 | 500×400 | 550×400 | 700×400 | 700×400 |

| slide | mm | 430×200 | 460×200 | 550×250 | 550×250 | 700×300 |

| Upper weight | kg | 50 | 50 | 100 | 100 | 100 |

| Max-hydraulic | MPa | 15.7 | 23.5 | 14.6 | 22 | 14.1 |

| Stopper | mm | 0〜90 | 0〜90 | 0〜120 | 0〜120 | 0〜120 |

| Oil tank | ℓ | 13 | 16 | 20 | 20 | 40 |

| Motor capacity | kw | 2.2 | 3.7 | 3.7 | 5.5 | 7.5 |

| weight | kg | 865 | 1115 | 1615 | 2065 | 2950 |

Size List/mm

| HOS | 500e | 800e |

| A | 1870 | 2100 |

| B | 3600 | 4500 |

| C | 700 | 1000 |

| D | 850 | 850 |

| E | 1280 | 1330 |

| F | 1250 | 1400 |

| G | 620 | 700 |

| H | 200 | 200 |

| I | 400 | 500 |

| J | 1415 | 1590 |

Standard equipment

| ・Dual hand operation panel |

・Failure diagnosis device | ・Safety block |

| ・Main breaker | ・Emergency stop button | ・Sequencer control |

| ・Electric lower limit stopper | ||

| ・Monochrome touch panel(pressure holding timer / abnormality display / accumulation timer / status monitor / trouble monitor / production counter) | ||

Standard options

| ・Special table | ・Special color | ・Touch panel |

| ・Actuating by external signal | ・Photo-electric safety device | ・Air blow circuit |

| ・Slide gravity fall prevention circuit | ・Vibration isolating mount | ・One cycle motion |

Special options

| ・Safety guard | ・Pressur control device | ・Touch panel colorization |

| ・Signal tower | ・Negative pressuer correspondence | ・Pressing ,speed digital setting |

| ・Air-cooled oil cooler | ・English specification | ・Slide position setting |

| ・oil cooler | ・English | ・Motion judgment |

| ・Pressing digital display | ・Different voltage specification | ・Adjust position storage |

H-S SERIES

▲ EFP300H

Main specifications

| EFP300H | ||

| pressing capacity | kN | 3000 |

| Pulling ability Maximum pressurization | kN | 40 |

| Daylight | mm | 400 |

| Stroke length | mm | 150 |

| Descent speed | mm/sec | 250 |

| Pressing speed | mm/sec | 0.01〜6.3 |

| Rise speed | mm/sec | 250 |

| Slide,Bolster demensions | mm | 400×400 |

| Traction motor | KW×P | 18.5×4 |

| Oil tank capacity | ℓ | 120 |

| Machine mass | kg | 10500 |

| Bottom dead center stop repetition accuracy | mm | ±0.01 |

| Set up | Bitless |

※This table slides.

H-S SERIES

▲ EFP450H

Main specifications

| EFP450H | ||

| pressing capacity | kN | 4500 |

| Pulling ability Maximum pressurization | kN | 90 |

| Daylight | mm | 450 |

| Stroke length | mm | 180 |

| Descent speed | mm/sec | 250 |

| Pressing speed | mm/sec | 0.01〜5.6 |

| Rise speed | mm/sec | 250 |

| Slide,Bolster demensions | mm | 500×500 |

| Traction motor | KW×P | 37×4 |

| Oil tank capacity | ℓ | 250 |

| Machine mass | kg | 16000 |

| Bottom dead center stop repetition accuracy | mm | ±0.02 |

| Set up | Bitless |

※This table slides.

H-S SERIES

▲ EFP1000H

Main specifications

| EFP1000H | ||

| pressing capacity | kN | 10000 |

| Pulling ability Maximum pressurization | kN | 150 |

| Daylight | mm | 550 |

| Stroke length | mm | 250 |

| Descent speed | mm/sec | 200 |

| Pressing speed | mm/sec | 0.01〜40 |

| Rise speed | mm/sec | 200 |

| Slide,Bolster demensions | mm | 800×800 |

| Traction motor | KW×P | 55×4 |

| Oil tank capacity | ℓ | 700 |

| Machine mass | kg | 40000 |

| Bottom dead center stop repetition accuracy | mm | ±0.08 |

| Set up | Bitless |

※This table slides.

EX100FB

▲ EX100FB

Main specifications

| EX100FB | ||

| Drive system | Electric servo type link drive | |

| Comprehensive ability | kN | 1000 |

| Stroke length | mm | 50 |

| Ability of lower cushion | kN | 10~310 |

| Stroke length of lower cushion | mm | 10 |

| Ability of upper cushion | kN | 10~270 |

| Stroke length of upper cushion | mm | 14 |

| Number of strokes | min-1 | 20~70 |

| Table dimensions | ||

| Upper table | mm | 480×520 |

| Lower table | mm | 480×520 |

| Die height | ||

| When the table is movable | mm | 138~264 |

| When the table is fixed | mm | 148~274 |

| Main motor | kN | 37(AC servo) |

※This table slides.

Standard equipment

| ・Roll feeder |

| ・Processing oil coating device |

| ・Scrap cutter |

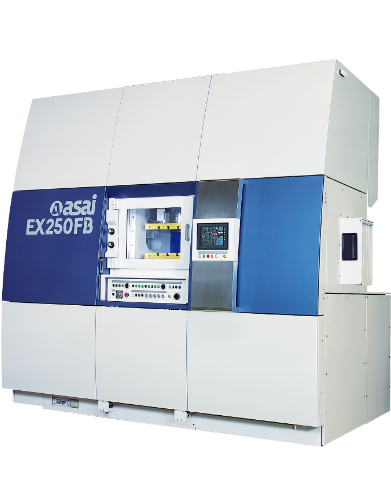

EX250FB

▲ EX250FB

Main specifications

| EX250FB | ||

| Drive system | Electric servo type link drive | |

| Comprehensive ability | kN | 2500 |

| Stroke length | mm | 61 |

| Ability of lower cushion | kN | 20~500 |

| Stroke length of lower cushion | mm | 15 |

| Ability of upper cushion | kN | 20~500 |

| Stroke length of upper cushion | mm | 13 |

| Number of strokes | min-1 | 20~60 |

| Table dimensions | ||

| Upper table | mm | 540×540 |

| Lower table | mm | 540×540 |

| Die height | ||

| When the table is movable | mm | 160×305 |

| When the table is fixed | mm | 175×320 |

| Main motor | kN | 37×2(AC servo) |

※This table slides.

Standard equipment

| ・Roll feeder |

| ・Processing oil coating device |

| ・Scrap cutter |

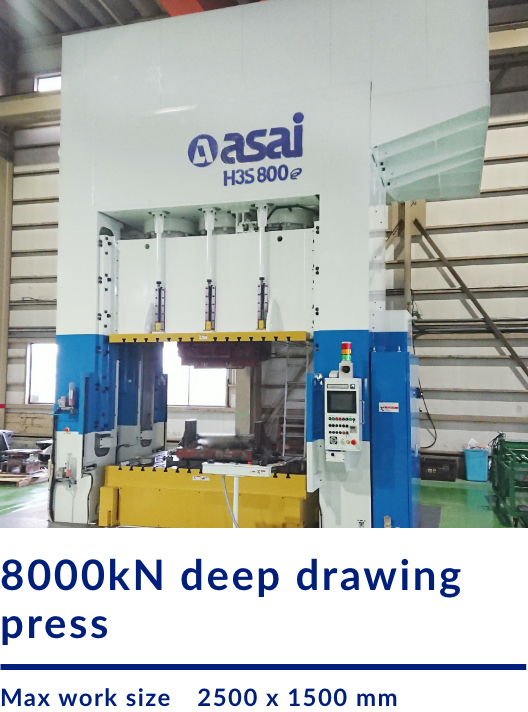

8000kN deep drawing press

【TABLE】2500 x 1500 mm

Main Specifications

・Equipped with multifunctional press controller "Eagle System"

・Stroke length 1100 mm

・ Die cushion capacity High pressure 300-2500kN Low pressure 50-300kN

Hot press for 15000kN try

【TABLE】3000 x 2000 mm

Main Specifications

・High-speed trial equivalent to actual hot stamping molding is possible

・Comes with a special sub-table

・Equipped with preventive maintenance function

10000kN caulking press

【TABLE】1200 x 1200 mm

Main Specifications

・Detects die deterioration by press motion judgment

・Adopts a fixed blanking type Photo-electric safety device for long parts

600kN punching press tandem line

【TABLE】750 x 500 mm

Main Specifications

・ Easy die replacement with die lifter

・ O frame specifications that suppress mouth opening

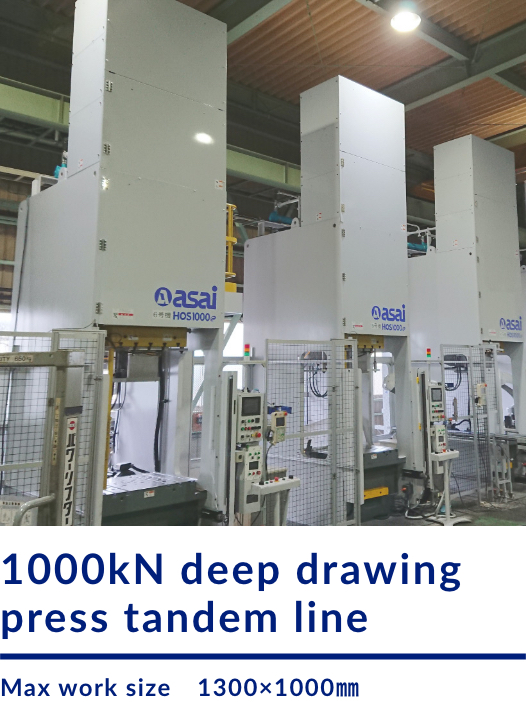

1000kN deep drawing press tandem line

【TABLE】1000 x 770 mm

Main Specifications

・Press line composed of HCS series special specification machines

・L-shaped line considering installation space

・Various process designs are possible by robot transfer

1300kN double acting hydraulic press

【SLIDE】 Inner: 800kN Outer: 500kN Die cushion / lower molding: 500kN

【Bolster】400 x 500 mm

Main Specifications

・Various operations are possible by 3-axis drive of inner / outer slide and die cushion / lower molding.

・Supports a wide range of test studies

・Accompanied by traceability data collection function